About

The Plastic Problem

Existing state of the art separation technology, such as near infra-red (NIR), cannot identify the problematic multi-layer flexible and black rigid plastic which act as harmful contaminants in the compounding process, blocking filters and preventing effective recycling.

This project addresses both these challenges through a combination of two technologies: BOSS (Baffled Oscillation Separation System) and PRE (Plastic Recycling Enhancer) additive.

Sed porttitor lectus nibh. Vivamus magna justo, lacinia eget consectetur sed, convallis.

The adoption of BOSS and PRE technologies will demonstrate at commercial scale the possibility to recycle plastic with:

– 95% pure recycled PE/PP plastic,

– specific MFI to meet the needs of different moulding processes,

– re-colouring to comparable virgin plastic,

– increased recyclability of/up to 7 times.

BOSS-2D

BOSS-2D technology separates the laminated and multi-layer flexibles from the comingled streams and produces two streams suitable for recycling as consumer non-food grade film.

Just 4% of post-consumer film packaging is currently recycled; by far the lowest percentage by plastic category.

Existing recycling technologies use Near infra-red (NIR) technology which cannot easily identify, and hence separate, laminate and multi-layer material. Together, this can account for up to 30% of the post-consumer plastic film fraction.

With no automated separation solution available on the market, post-consumer flexibles are either sent for incineration or exported to overseas markets where it can be dumped in landfill and waterways creating long term local and global environmental problems.

LIFE BOSS aims to develop and upscale a BOSS-2D plant which will act as a complete recycling and production line for post-consumer mixed flexible waste plastic.

The BOSS-2D demonstration plant will be developed in a new recycling plant in Glasgow, UK with three distinct stages:

Stage 1:

2D Shred & Wash Line

Stage 2:

BOSS-2D Line

Stage 3:

HDPE and PP Compounding Lines

BOSS-3D

Bulky mixed rigid plastic accounts for 70% of plastics produced and makes up 60% of the waste plastic sent to landfill or incineration in the EU today.

Existing solutions either cannot technically separate this plastic or cannot do so in a scalable, economically viable way.

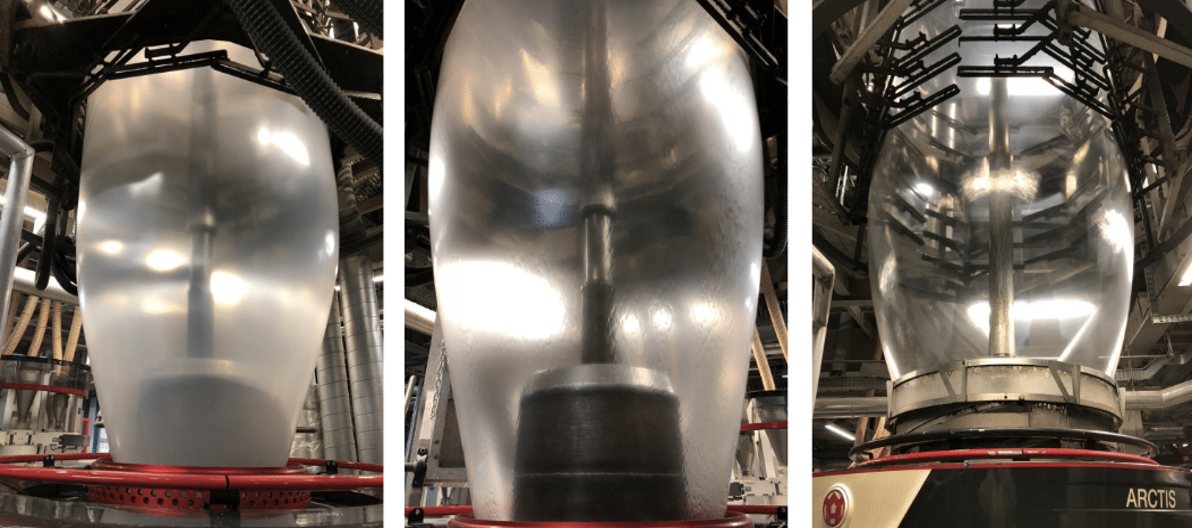

BOSS-3D technology separates the ‘hard to recycle’ stream of mixed rigid waste plastics using baffle oscillation.

Baffles oscillate to create the specific force necessary to separate the mixed material into two independent streams of PE and PP each with >95% purity.

Plastic Recycling Enhancer (PRE)

PRE is a monomer grafted to a polymer carrier that becomes rheologically active under two specific process conditions: shear and temperature.

It forms a micron layer to a specific melt flow index while the recycle plastic in the moulding process. The non-chemical nature of the additive ensures no loss in the mechanical properties of the plastic and enhances the ability to be recycled again.

PRE disperses the original masterbatch throughout the entire structure of the polymer matrix, thereby diluting the original colour and enabling re-colouring to specific colours.

Processing effect of PRE – BOSS-2D

This programme is funded by the LIFE Programme: LIFE20 ENV/UK/000630*